Leather and leather goods production clusters in India, concentrated in Uttar Pradesh and Tamil Nadu are the major sources of India’s exports to the international markets and brands in the EU, US, and the UK. However, the working conditions in which leather workers operate do not paint the industry in a good light. Moreover, the complexity of the supply chains in the leather industry with multilevel stakeholders involved such as contractors, sub-contractors, daily-wagers, home-based workers, etc., make it difficult to conduct a comprehensive social audit or due diligence that is inclusive.

India is one of the largest exporters of leather and leather goods in the world. The leather industry employs more than a million people and is one of the most labor-intensive intensive sectors. Leather and footwear manufacturing in India is arranged in geographical clusters, with tanneries and shoe manufacturing factories concentrated in a few towns and cities. Kanpur and Agra in the northern state of Uttar Pradesh and Ranipet, Chennai, and Ambur in the southern state of Tamil Nadu are major hubs for leather production. The industry, which started to grow during the 1950s, used to cater to domestic demand but is now well-linked with global supply chains. Many international brands and retailers based in the European Union, UK, and US source leather and leather goods from India. Despite the remarkable growth witnessed by the industry in recent times, serious violations with respect to workers’ rights have been documented.

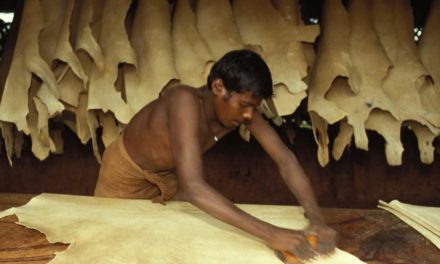

Precarious working conditions

Low wages, occupational health, and safety risks, involuntary overtime, child labour, lack of freedom of association, and absence of grievance redressal mechanisms are some issues prevalent in the industry. Despite about 70 percent of workers in shoe-making units being women, most companies fail to comply with legal maternity and childcare norms. Tanneries are prone to various kinds of occupational health and safety hazards due to the use of harmful chemicals such as Chromium.

Between 2011 and 2018, 19 workers are reported to have lost their lives due to accidents in tanneries in Tamil Nadu.¹ Studies have also indicated that inadequate safety measures in tanneries cause diseases such as eczema, skin allergies, musculoskeletal disorders, upper respiratory infections, and bronchial asthma among workers. Since a large number of workers are employed informally as daily wagers and home-based workers, they are excluded from social security schemes and health insurance. Medical care remains elusive to a majority of workers in the leather industry.

The long road to transparency

Lack of transparency and traceability in the supply chain is a serious issue. Brands and retailers sourcing from India often do not provide information about local suppliers. In some cases, the brands publish only the details of their first-tier suppliers and tend to shirk their responsibility towards workers in the lower ends of supply chains. These supply chains are complex and often difficult to trace. While there are bigger suppliers who run integrated shoemaking and tanning units, the practice of subcontracting is also common. Subcontractors who cater to large suppliers operate in small-scale units called ‘job work centers’. Homeworking too is widespread; subcontractors employ a large number of home-based women workers. The informal nature of such work results in subcontractors escaping the purview of labour laws and the scrutiny of government departments.

Social audit and its pitfalls

Some brands that source from India, do conduct social audits. These audits are typically done by third-party firms, and in some exceptional cases, brands conduct their own audits based on their Codes of Conduct. However, the major drawback of social audits is that it is restricted to the first tier of the supply chain, and it fails to look beyond the factory walls. In most cases, even tanneries are not covered within the scope of audits. A large number of workers in tanneries and job work centers, and those employed as home-based workers, are left out of the process.

The credibility and accountability of social audits are therefore questionable, and there is little evidence to prove that they have improved working conditions. For example, most leather factories have no trade unions, and workers are unable to exercise their right to freedom of association. Social audits consistently miss out on crucial aspects of workers’ rights such as gender discrimination, and workplace harassment and abuses.

Due diligence: A far cry from the present

The United Nations Guiding Principles on Business and Human Rights (UNGP) and the OECD guidelines require all businesses, including transnational corporations, to perform human rights due diligence to identify and remediate any adverse impact of their activities on workers and communities. However, human rights due diligence is hardly evident in the leather industry in India. International brands and retailers are evasive about taking responsibility for their supply chains and do not require that their suppliers make improvements in working conditions.

Two civil society organizations – Homeworkers Worldwide and Cividep India–with support from multi-stakeholder platform Ethical Trading Initiative (ETI), collaborated on a project with some brands. The project documented practices at the factory level and in informal chains employing home-based workers and identified some adverse labour rights risks and impacts. Although small, the project stands as an example for multi-stakeholder collaborations aimed at due diligence.

More brands and retailers should perhaps emulate this approach of fostering collaborations with civil society organizations aimed at joint investigations, and adopt policies that demonstrate their commitment to due diligence. Responsible brands should also encourage their suppliers to adopt practices that improve working conditions, in line with international labour standards.

Pradeepan Ravi is a Project Coordinator at Cividep India, working in the leather sector.